Main Feature

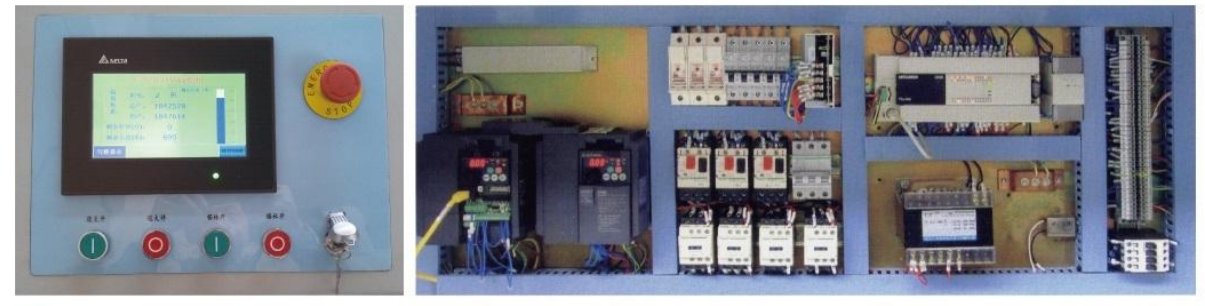

1.Microcomputer controls and touch screen display relative parameter.

2.The special wolkframe with high strength, easy to adjust and convenient to take out the under casing of the cylinder.

3.Sealed later shield of the cylinder to avoid the fly on it.

4.Suitable for chutes feed or two lap feed.

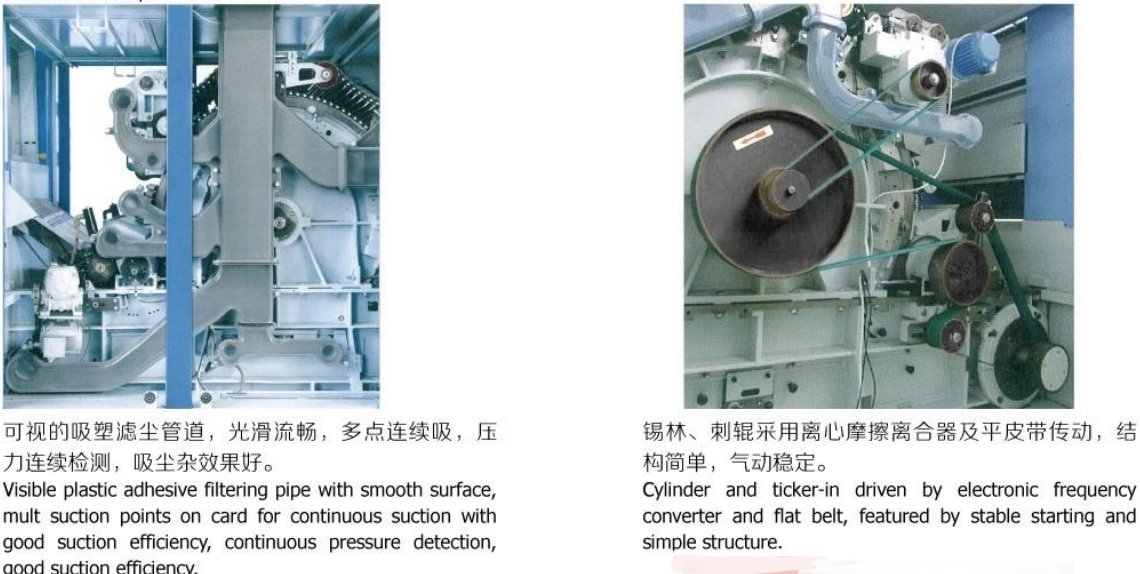

5.Visible plastic adhesive filtering pipe with smooth surface, multi suction point on card for continuous suction with good suction eflciency. Continuously pressure detection.

6.Reversed revolving flats increase carding action and improve web quality.

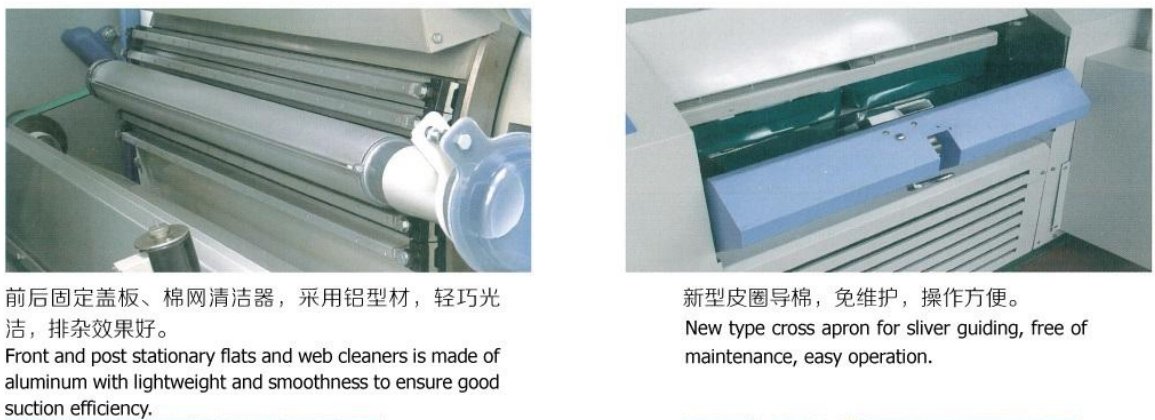

7.Front and post stationary flats, web cleaners and carding segment under lickel-in are ftted.

8.0ptimum designed constructions of the cylinder and doffer ensure its precision.

9.Newly designed profle with beatiful appearance.

10.Front and post stationary flats and web dleaners are made of aluminum lightweight and smooth to ensure good suction efficiency.

11.New type cross apron for sliver guiding, free of maintenance, easy operation.

12.Long-term and short-mixed loop autoleveller is equipped.

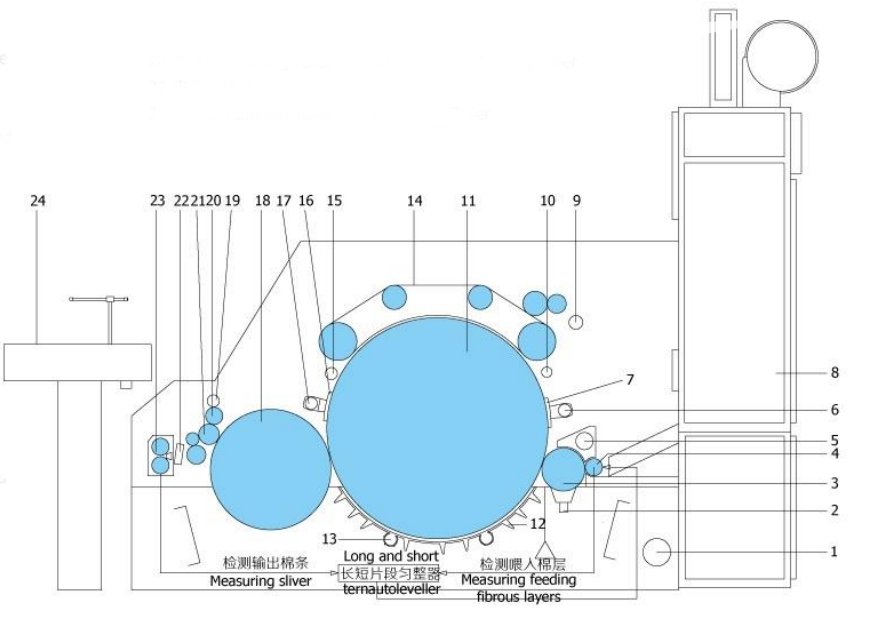

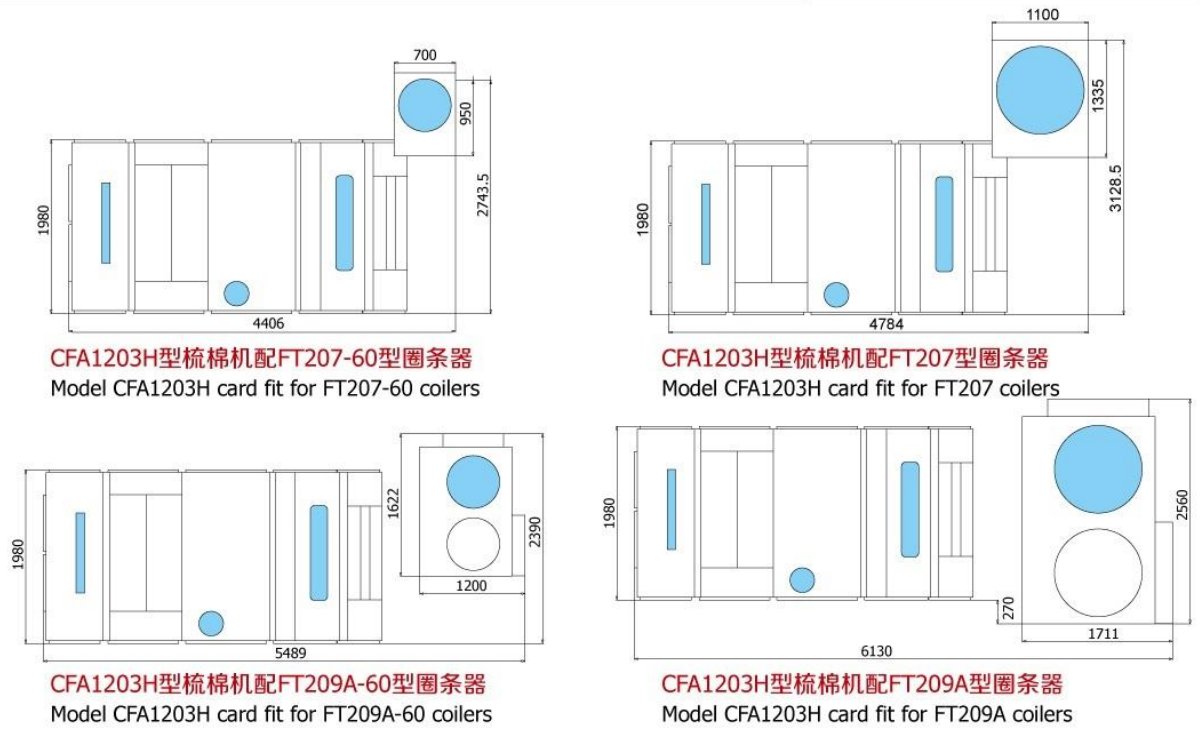

Plane Diagram

1.Suction point for under-card waste

2.Carding segment under licker-in

3.Licker-in

4.Feed roller

5.Suction point for licker-in hood

6.Post web deaner

7.Post stationary flat

8.Chute feeder

9.Suction point for flat strips

10.Suction point for flat impurities

11.Cylinder

12.Enclosed undercasing for cylinder

13.Suction points for cylinder undercasing

14.Flats

15.Suction point for flat impurities

16.Front stationary flat

17.Front web cleaner

18.Doffer

19.Suction point for cleaning roller

20. Cleaning roller

21.Stripping roller

22. Cross apron unit

23. Calender roller

24. Coiler

Fitting

Autoleveller: model CYZ- 306 autoleveller with open-and-close loop is used to detect thickness of cotton layer feed and sliver and to control feed roller speed through computer, so as to realize short and long term levelling to enhance sliver evenness.

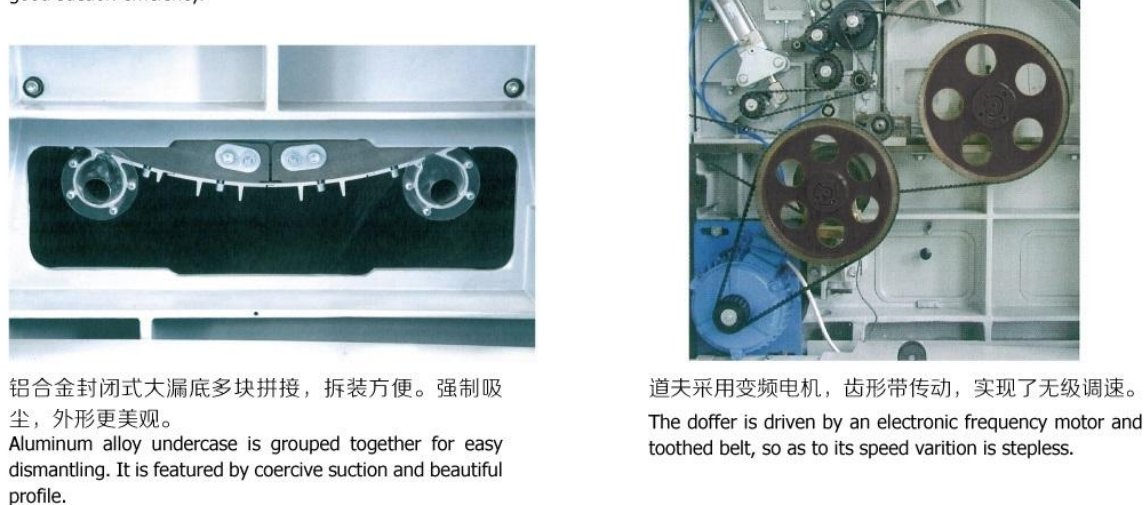

Electric control cabinet

There are imported PLC and imported inverters in the electronic control cabinet of card CFA1203H. It controls doffer and feed motor's speed to make a stepless vaiable-speed and run it at the ratio, with a smooth speed up and down and a good braking performance, it is running steadily and reliably.

The imported display screen is erected on front safety cover in the left of machine. It can control each motor. It can display all data on dynamic technology and take an alarm for all faults and full-can status. Control ceter of whole machine is an imported programable controller, which operates simply and reliably.