Application

CFA009 series bale plucker as the first process of blowroom & card is suitable to each kind of cotton and chemical, viscose fibre length less than 76mm. The pluck arm, mounted with two beaters can lift and revolve 180 degrees. The pluck arm moved to and back to pluck fibre above bale. The fibre plucked are sucked into the front feeder by air current throught transport duct for further process.

Main Feature

For two plucker beaters, no matter plucker carrier moves either forward or backward, one plucker beater always plucks in clockwise, but another plucks in anticlockwise. Beater hanging device driven by motor rises up anticlockwise plucking beater.

The height can be adjusted according to requirements in order to prevent beater more plucking in depth and keep the load of two beaters basic equal in working to reduce abrasion of spare parts such as belt and bearings etc. Dual saw-blade beater plucks flock evenly up and down with high and small dispersion rate in order to achieve plucking block finely, lttle and evenly from beginning in blowing-carding line technology. Intermittent vertical stroke of detacher can be adjuster steplessly within the range of 0.1~19.9mm/times. The travel speed of plucker carrier is adjusted by frequency inverter at 5~15m/min.

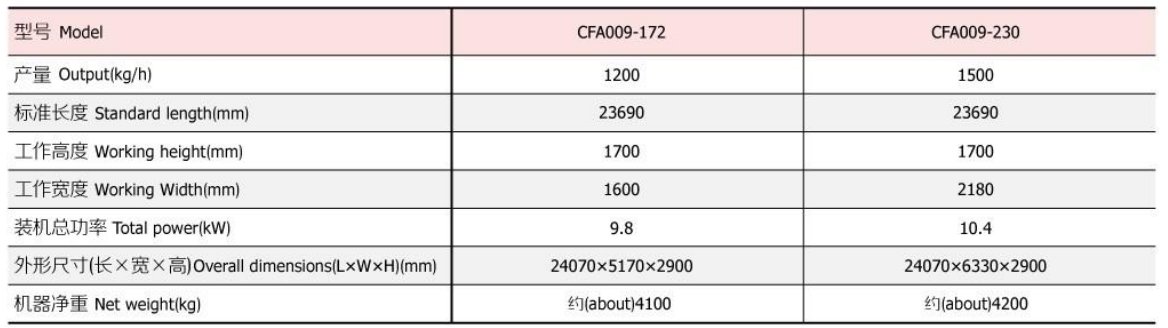

Main Technical Parameters

Note: It can increase or decrease gradually in length 2475mm/knots.

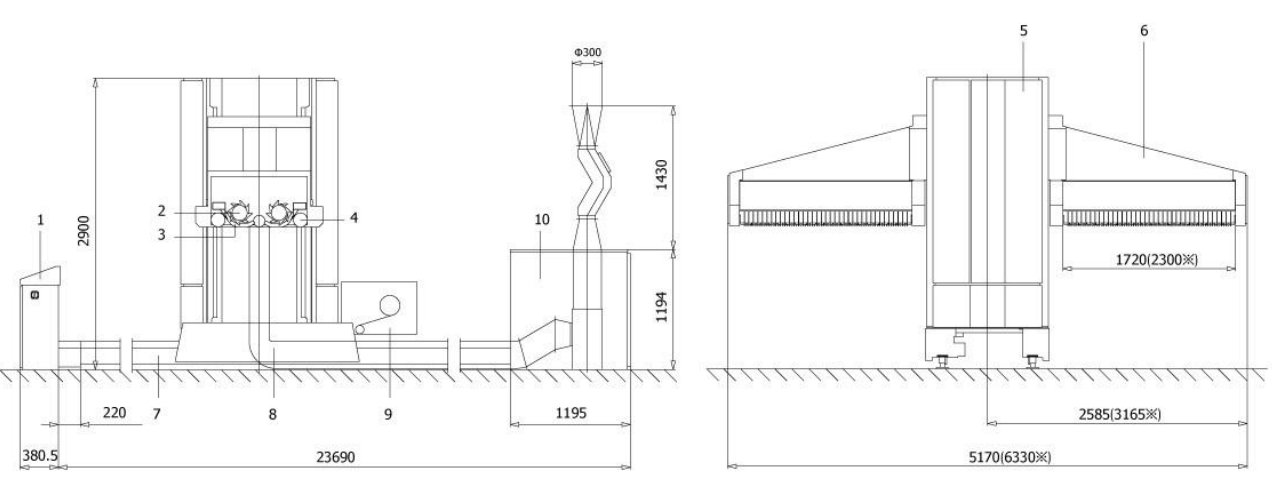

Plane Diagram

1.Electric appliance operating table 2.Beater 3.Rib 4.Turret 5.Turret 6. Bale rack

7.Air duct and ground rail 8.Walking Carriage 9.Cover tape wound 10.Cotton outlet

CFA009-2300 Note: Belt ※size for CFA009- 2300 model size